ADNOC Gas is utilizing additive manufacturing (3D-printing) at a number of sites to simplify logistics, reduce inventories of physical parts and optimize costs.

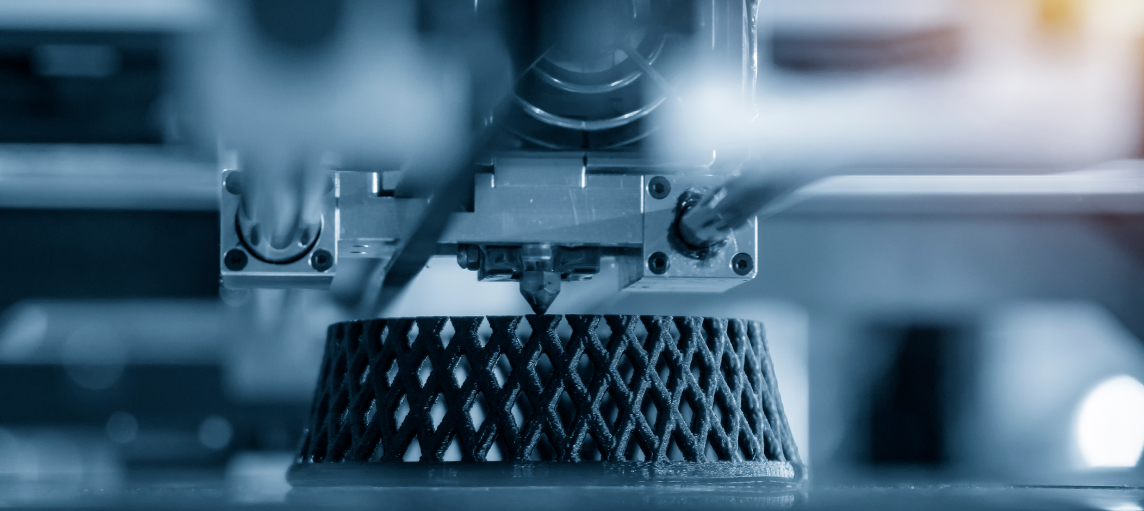

Additive manufacturing, also known as 3D printing, offers a transformational digital solution to the design and production of parts and our maintenance supply chain. The local manufacturing process leverages digital 3D models, automated machines and software to create custom-made components to order that are more cost effective and have greater functionality than traditionally manufactured parts.

In 2021, the team at the Habshan and Bab gas plant adopted this technology and hundreds of parts have since been scanned and stored digitally. Whenever these parts are needed, they can be accessed in a virtual warehouse and printed digitally utilizing polymers or metals. Parts can be created on demand with minimal lead times, eliminating the need to mobilize them from overseas and reducing inventories held on site.

Following a pilot project, 3D printing has also been adopted in our Das Island operations, with parts commissioned from 3D workshops in UAE already producing very substantial reductions in lead times and costs. The feasibility of onsite 3D manufacturing on Das Island is being pursued.

Reflecting the vital importance of spare parts for uninterrupted asset integrity and HSE performance, 3D printing improves performance and functionality, and underpins business continuity while reducing excess inventory, logistics and storage costs. In addition, this technology offers the ability to produce parts built with advanced materials and geometries that offer greater strength and corrosion resistance.